In 2015 Dawson Foundation Repair introduced the “Dawson Driven Pile System” that was a significant technical upgrade to this commonly used foundation repair system. The changes that have been made to this system are revolutionary. Dawson consulted structural engineers and industry experts to incorporate engineering design improvements that make the “Dawson Driven Pile System” significantly better than the other pushed piling systems on the market. To put it in plain English, we have taken a poorly engineered system and improved it to the point where it can succeed.

The pushed piles system has always been a quick and lower cost repair system. But this system also has its inherent drawbacks that make it a marginal system at best. So the Dawson team asked how they could make it better. After much discussion and analysis they designed a system that addresses or eliminates all of the significant drawbacks of the pushed pile system except one*. Dawson has created the best pushed pile system on the market. So let’s take a look at what has been accomplished.

Improvements Made by the Dawson Driven Pile System

1) Soil Test – Although a soil test is not technically part of a pushed pile system, it is extremely helpful to know the depth the piles must be driven until they reach stable soil. It is also very important to know if there is any sand or water near the soil surface. Dawson performs a soil test on every home and commercial building before beginning their repair work. It is simply the wise thing to do and Dawson is the only foundation company that performs this task on every job site.

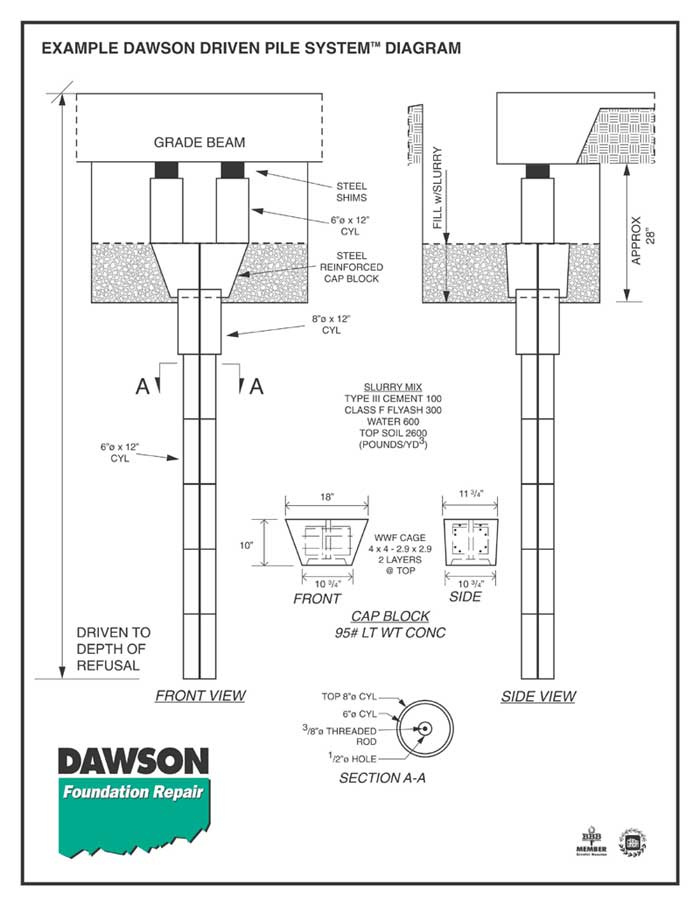

2) Vertical Alignment – Dawson is using a threaded rod that runs through each concrete cylinder and connecting all of the cylinders. This significantly improves the probability that all of the cylinders will align in a vertical column. At this time there is no method to prove or confirm that the cylinders are in vertical alignment*.

3) Cap – Steel Reinforced – The cap is a rectangular block of concrete that rests on the top of the vertical column of driven concrete piles. It transfers the weight of the concrete slab and building structure to the column of concrete cylinders. It is critical that this block of concrete not crack or crumble under these great stresses so Dawson has decided to reinforce the cap with a steel cage, which makes the cap significantly stronger. The cap also functions as a spread footing by distributing the weight of the house over a larger surface area.

4) Cap Grouting / Prevent Water Penetration – Dawson will also pressure grout the area around the cap of the pier with high strength concrete grout slurry. This grouting essentially expands the size of the cap by five inches on each side, making it a much larger and wider spread footing. This process will help prevent water from draining down the cylinder holes of the concrete piles and thereby avoid soil compaction. The larger surface area of the cap will also help prevent surface rain and water from seeping down the sides of the column of piles, which would reduce surface friction between the cylinders and the surrounding soil.

5) Factor of Safety – Improved Factor of Safety for the Dawson Pushed Piles System. What does this mean? Older pushed pile systems have a factor of safety = 1. That means the installed repair system can never support more that the weight of the home at the time of installation. It means that if you buy a piano an put it in an area where the foundation slab was repaired you have just created a failure situation. The driven concrete cylinders cannot support any additional weight. This becomes very problematic when a garage has its concrete slab supported by older pushed pile systems. As soon as the owner parks a car in the garage the older concrete piling system cannot support the additional weight and will begin to fail.

The Dawson Pushed Pile System has a calculated Factor of Safety of between 4 to 8, which means that our system can support 4 to 8 times the weight of the house after installation. We cannot overstate how important this improvement is for homeowners and other property owners. You can buy a piano without worrying, or park your cars in your garage because our system will support far more weight than older concrete pile systems.

6) Mud Pumping – Dawson will also fill voids that are left after the leveling of a concrete slab foundation. Remember, the slab has “fallen” (settlement) in some areas because the clay soils have compacted and / or shrunk over time. The “mud” is a soil and concrete mixture that will replace the missing support between the bottom of the concrete foundation and the soil underneath. This is an extra service that only a few foundation repair companies provide in the Texas market.

In conclusion, Dawson has taken a poorly engineered system that is prone to failure and improved the design and performance to an acceptable level. The new “Dawson Driven Pile System” is now available to home and other property owners throughout the state of Texas.

* The one issue that Dawson has not resolved is the lack of confirmation of a proper installation. In fact, no foundation repair contractor has resolved this issue. That is, when the concrete cylinders are driven into the ground there is no test or confirmation method to confirm that they have been driven in a vertical column and not skewed off at an angle. We call this the “verification of the vertical.”

The Dawson Driven Pile System is also backed by the

Dawson Lifetime Service Agreement

click here to return to the Home Page